In Which Welding Processes Is Continuous Consumable Electrode Used

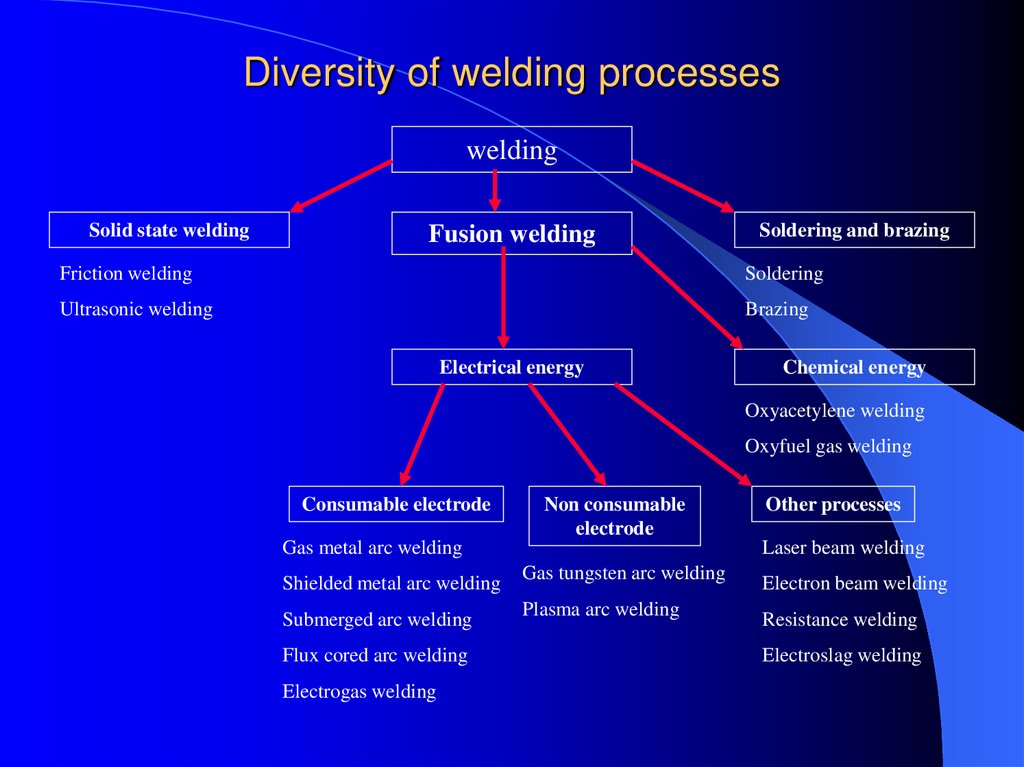

Shielded Metal Arc Welding SMAW Gas Metal Arc Welding GMAW both MIG and MAG Flux-cored arc welding FCAW Submerged arc welding SAW Electroslag welding ESW Electro-gas welding EGW Arc welding processes that employ a non-consumable electrode. In this type of welding process a continuous consumable wire electrode is used.

Solved Which Of The Following Are Welding Processes Does Not Use Co

In shield metal arc welding SMAW also known as a stick electrodes are consumable which means that the electrode is consumed during its use and melts with the weld.

. Arc welding processes that employ a consumable electrode. Flux is commonly employed. A consumable electrode is a metal that supplies electricity to the weld joint.

This is the automatic equivalent of the manual metal arc process but instead of the electrode being hand-held it is stored on a drum and incorporated into a continuous automatic feed system. Matching Strength of Consumables to Metals. Similarly what are consumables in welding.

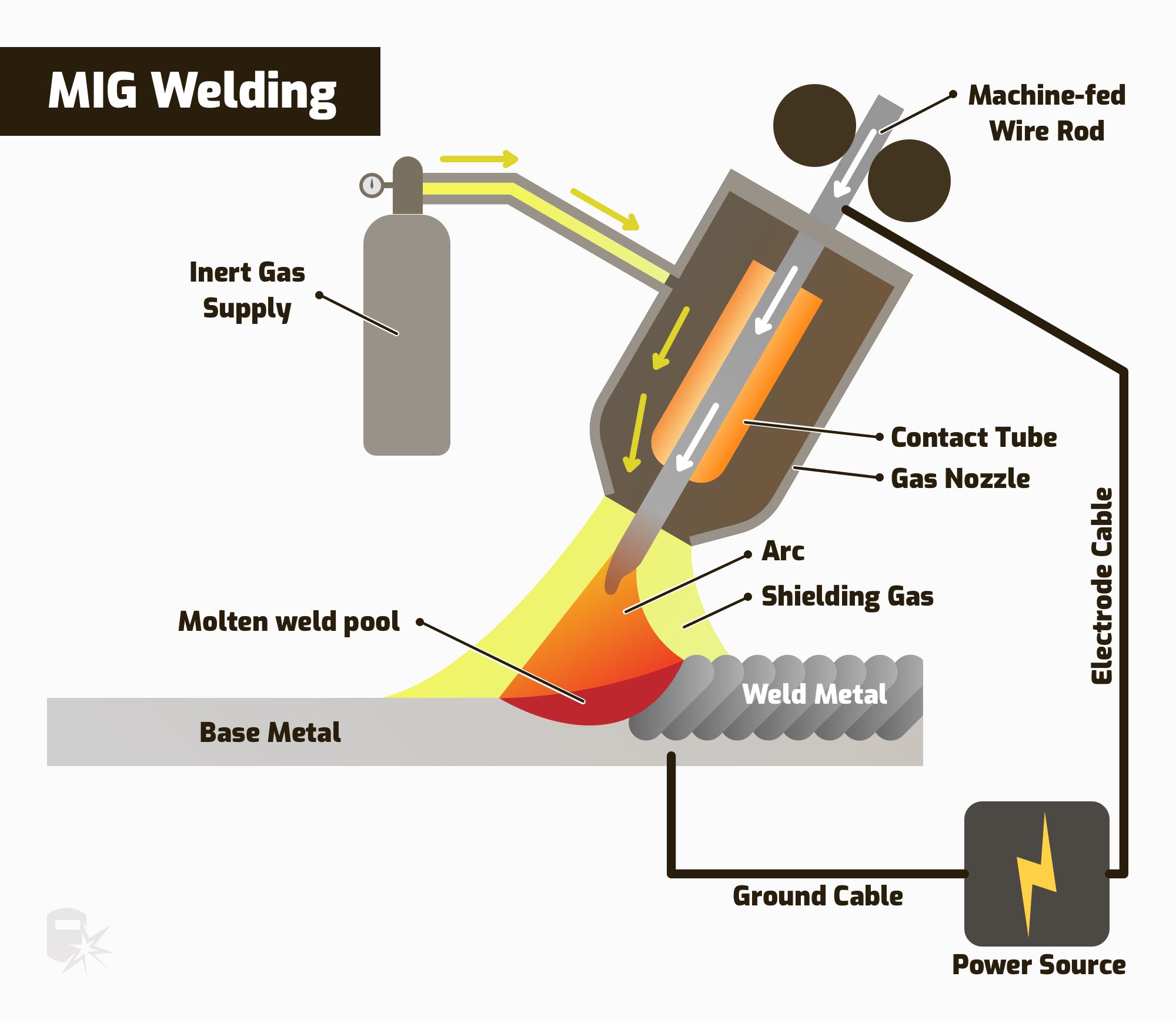

Metal Inert Gas MIG welding is an Electric arc welding process that uses consumable electrodes. LBW Deep penetration fast high equipment cost. Submerged Arc Welding SAW.

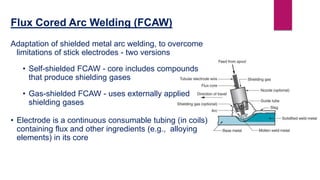

Created as an alternative to SMAW FCAW uses a continuously fed consumable flux cored electrode and a constant voltage power supply which provides a constant arc length. Gas metal arc welding is a process that uses a wire consumable with a wire spool feeding the wire into the weld joint. In this process a continuous solid wire electrode is used in the form of wire as a welding consumable.

However the electrode itself undergoes melting when it is near the weld pool. Therefore choosing the right weld electrode is crucial for creating a clean strong weld. Mig welding wire is available in various sized spools that suit specific types of MIG welder.

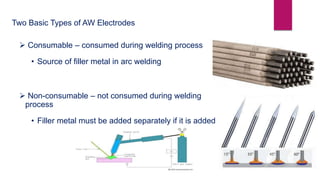

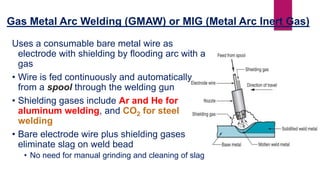

In this process the arc is formed between a continuous automatically fed metallic consumable electrode and welding job in an atmosphere of inert gas and hence this is called metal inert gas arc welding MIG process. The primary electrode types used in welding are consumable electrodes and non-consumable ones. Along with ensuring the consumable has the same melting point as the base metal its also critical to match the strength of the filler to the strength of the metals being welded to get the best results.

However welding electrodes are also classified depending on their application and type of weld. Most generally utilized Electrodes 6010 Electrodes This kind of Electrode is regularly utilized for general welding applications that dont require any extraordinary highlights. Welding is a sculptural process wherein thermoplastics or metals are joined together with the help of coalescence.

This process either uses a shielding gas or just the gas created by the flux to provide protection from contamination. Where the two base metals are melted together to form the weld joint. Gas metal arc welding GMAW or Metal inert gas arc welding MIG.

Joining rails in situ by liquid metal Induction welding. Gas Metal Arc Welding GMAW or Metal inert or active gas welding MIGMAG. Gas Metal Arc Welding GMAW is also known as Metal Inert Gas Welding or metal active gas welding MIG MAG welding.

The consumable electrodes are made of a material that is good with the base material being welded and is secured with the transition. A continuous solid wire electrode or definite length solid consumable electrodes are fed into the weld pool from a welding gun. In Tungsten Inert Gas welding TIG electrodes are non-consumable.

Mig Welding electrodes Continuous Wire-feed consumable electrodes are used for welding mild steel stainless steel and aluminum. Uses a consumable bare metal wire as electrode with shielding by flooding arc with a gas Wire is fed continuously and automatically from a spool through the welding gun Shielding gases include argon and helium for aluminum welding and CO 2. Welding rods are a vital part of the welding process.

Gas metal arc welding GMAW or Metal inert gas arc welding MIG. Typical types of stick electrodes include Low hydrogen electrodes and iron powder electrodes. It is a semi-automatic welding process.

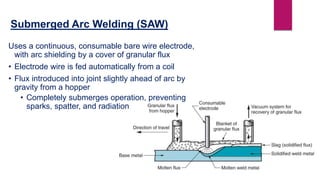

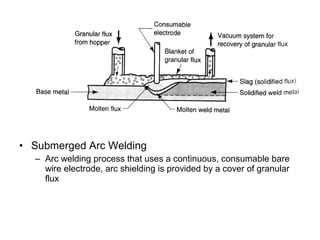

In this process the arc is formed between a continuous automatically fed metallic consumable electrode and welding job in an atmosphere of inert gas and hence this is called metal inert gas arc welding MIG process. SAW is an arc-welding process that uses a continuous consumable bare wire electrode and arc shielding is provided by a cover of granular flux. Filler metals are used during the course of welding.

In MIG welding the melted electrode facilitates the joining of the two metals. Automatic with a continuous coated Electrode. Hence it gets consumed during the welding process.

11 rows continuous consumable electrode Heavy plate fabrication construction shipbuilding Flow welding previously cast welding Distortion is minimized and the thermal cycle is relatively benign. Externally supplied shielding gas such as Argon Helium Carbon dioxide or a mixture. IW Laser beam welding.

To prevent the flux breaking away from the coiled electrode spin-wires are helically wound around the outside of the flux which acts. Why are the temperatures much higher in plasma arc welding thatn in other AW processes. A shielding gas generally argon Ar or sometimes mixture of argon and carbon dioxide are blown through a welding gun or torch to the weld.

SAW is an arc-welding process that uses a continuous consumable bare wire electrode and arc shielding is provided by a cover of granular flux.

The Mig Welding Process Chavda Et Al 2014 Download Scientific Diagram

Api 653 Exam Chapter 13 Introduction To Welding Api Rp 577 Upweld

Welding Processes Input And Output Download Scientific Diagram

Different Types Of Welding Processes With Pictures

Unitherm Ceramic Fiber Insulation Blanket Roll 8 Density 2300 F 1in X24in X25ft For Kilns Ovens Furnaces Forges Stoves Cf8 1 24x25 The Home Depot Ceramic Fiber Blanket Insulation Ceramic Fiber Blanket

4 Main Types Of Welding Processes With Diagrams

Arc Welding Process An Overview Sciencedirect Topics

Unitherm Ceramic Fiber Insulation Blanket Roll 8 Density 2300f 1in X24in X60in For Kilns Ovens Furnaces Forges Stoves Cf8 1 24x60in Ceramic Fiber Blanket Insulation Ceramic Fiber Blanket

Unitherm Ceramic Fiber Insulation Blanket Roll 8 Density 2300f 1in X24in X60in For Kilns Ovens Furnaces Forges Stoves Cf8 1 24x60in Ceramic Fiber Blanket Insulation Ceramic Fiber Blanket

Gas Metal Arc Welding Gmaw Is More Popularly Known By The Name Metal Inert Gas Mig Welding And Its Other Name Is Gas Metal Arc Welding Arc Welding Welding

Welding Process Prezentaciya Onlajn

Metal Forming Processes Are Broadly Divided Into Bulk Metal Forming And Sheet Metal Forming Processes Shearing Piercing Blan Sheet Metal Metal Forming Sheet

Comments

Post a Comment